Next: 8.1.2 The n=2 times Up: 8.1 Illustrative problems Previous: 8.1 Illustrative problems

(see Fig. 8.7(b)) at which the first plastic moment occurs.

(see Fig. 8.7(b)) at which the first plastic moment occurs.

Problem Solving.

Now we apply the two load cases shown in Fig. 8.7.

or

or

will appear.

We find that this is node 4:

will appear.

We find that this is node 4:

(see Fig. 8.2(a)).

Next we find the load factor

(see Fig. 8.2(a)).

Next we find the load factor

for a full plastic moment

for a full plastic moment

to appear at node 4:

to appear at node 4:

(see Fig. 8.2(a)).

(see Fig. 8.2(a)).

or

or

will appear. We find that this is node 5

(see Fig. 8.2(b)).

We also find that to achieve

will appear. We find that this is node 5

(see Fig. 8.2(b)).

We also find that to achieve

at this node,

at this node,  is needed to add, and that

is needed to add, and that

as shown in Figs. 8.2(b) and 8.3(a).

as shown in Figs. 8.2(b) and 8.3(a).

We use the EST method described in Chapter 3, ``Statically indeterminate problems'', and carry out the following steps of calculations:

1. Input data for the GNU Octave program spESTframeSn3LaheWFI.m are given in excerpts from the program: element and nodal loads - excerpt 8.1; nodal coordinates - excerpt 8.2; element properties, topology and hinges - excerpt 8.3.

Number_of_frame_nodes=5 Number_of_elements=4 Number_of_support_reactions=6 spNNK=12*Number_of_elements+Number_of_support_reactions; Number_of_unknowns=spNNK Displacements and forces are calculated on parts ''Nmitmeks'' of the element Nmitmeks=4 Lp=10.0; % graphic axis # ---- Load variants ----- load_variant=1; #load_variant=2; # --- Element properties ---

EIp=20000 # kN/m^2 EIr=40000 # kN/m^2 EAp=4.6*10^6 #EAp=4.6*10^15; EAr=6.8*10^6 #EAr=6.8*10^15; GAp=0.4*EAp GAr=0.4*EAr

baasi0=EIp/4 # scaling multiplier for displacements # baasi0=1.0; h=4.0; l=4.0; l1=l % l l2=l % l Mplr=30.0 # The plastic moment of beam Mplp=15.0 # The plastic moment of column # Loads F2s=0.5; F3s=1.0;

switch (koormusvariant)

case{1}

disp('--- ')

disp(' Load variant 1 ')

disp('--- ')

#

# Element load in local coordinates

# qz qx qA qL

# Uniformly distributed load in local coordinate z and x directions

Loadsq on element=4;

esQkoormus=zeros(LoadsqONelement,4,ElementideArv);

esQkoormus(1,1:4,1)=[0.0 0.0 0.0 4.0]; esQkoormus(1,1:4,2)=[0.0 0.0 0.0 4.0]; esQkoormus(1,1:4,3)=[0.0 0.0 0.0 4.0]; esQkoormus(1,1:4,4)=[0.0 0.0 0.0 4.0];

# # Point load in local coordinate z and x directions kN # Fz, Fx, aF (coordinate of the point of force application) LoadsF on Element=5; esFjoud=zeros(LoadsF_on_Element,2,ElementideArv);

esFjoud(1,1:3,1)=[0.0 0.0 4.0]; esFjoud(1,1:3,2)=[0.0 0.0 4.0]; #esFjoud(2,1:3,2)=[0.0 0.0 4.0]; esFjoud(1,1:3,3)=[0.0 0.0 4.0]; esFjoud(1,1:3,4)=[0.0 0.0 4.0];

# # Node forces in global coordinates # sSolmF(forces,1,nodes); forces=[Fx; Fz; My] sSolmF = zeros(3,1,SolmedeArv);

#sSolmF(:,1,1)= 0.0; sSolmF(1,1,2)= F2s; # 0.5; sSolmF(2,1,3)= F3s; # 1.0; #sSolmF(:,1,4)= 0.0 #sSolmF(:,1,5)= 0.0

# #s1F(1,1,1)=0.0; # force Fz #s1F(2,1,1)=0.0; # force Fz #s1F(3,1,1)=0.0; # force My # Support shift - tSiire # Support shift is multiplied by scaling multiplier tSiire = zeros(3,1,SolmedeArv);

#tSiire(:,1,1)= 0.0 #tSiire(2,1,1)= 0.01*baasi0 #tSiire(:,1,2)= 0.0 #tSiire(:,1,3)= 0.0 #tSiire(:,1,4)= 0.0 #tSiire(:,1,5)= 0.0

case{2}

disp('--- ')

disp(' Load variant 2 ')

disp('--- ')

load myfile30.mat

plastF1F2;

Flambda0=plastF1F2(1,1);

F2s03=plastF1F2(1,2)

F3s03=plastF1F2(1,3)

# Element load in local coordinates # qz qx qA qL # Uniformly distributed load in local coordinate z and x directions Loadsq on element=4; esQkoormus=zeros(LoadsqONelement,4,ElementideArv);

esQkoormus(1,1:4,1)=[0.0 0.0 0.0 4.0]; esQkoormus(1,1:4,2)=[0.0 0.0 0.0 4.0]; esQkoormus(1,1:4,3)=[0.0 0.0 0.0 4.0]; esQkoormus(1,1:4,4)=[0.0 0.0 0.0 4.0];

# # Point load in local coordinate z and x directions kN # Fz, Fx, aF (coordinate of the point of force application) LoadsF on Element=5; esFjoud=zeros(LoadsF_on_Element,2,ElementideArv);

esFjoud(1,1:3,1)=[0.0 0.0 4.0]; esFjoud(1,1:3,2)=[0.0 0.0 4.0]; #esFjoud(2,1:3,2)=[0.0 0.0 4.0]; esFjoud(1,1:3,3)=[0.0 0.0 4.0]; esFjoud(1,1:3,4)=[0.0 0.0 4.0];

# # Node forces in global coordinates # sSolmF(forces,1,nodes); forces=[Fx; Fz; My] sSolmF = zeros(3,1,SolmedeArv);

#sSolmF(:,1,1)= 0.0; sSolmF(1,1,2)= F2s03; sSolmF(2,1,3)= F3s03; #sSolmF(:,1,4)= 0.0 #sSolmF(:,1,5)= 0.0

# #s1F(1,1,1)=0.0; # force Fz #s1F(2,1,1)=0.0; # force Fz #s1F(3,1,1)=0.0; # force My # Support shift - tSiire# # Support shift is multiplied by scaling multiplier tSiire = zeros(3,1,SolmedeArv);

#tSiire(:,1,1)= 0.0 #tSiire(2,1,1)= 0.01*baasi0 #tSiire(:,1,2)= 0.0 #tSiire(:,1,3)= 0.0 #tSiire(:,1,4)= 0.0 #tSiire(:,1,5)= 0.0

otherwise

disp(' No load variant cases ')

endswitch

#==========

# Nodal coordinates

#==========

krdn=[# x z

0.0 0.0; % node 1

0.0 -4.0; % node 2

4.0 -4.0; % node 3

8.0 -4.0; % node 4

8.0 0.0]; % node 5

#==========

#==========

# Restrictions on support displacements (on - 1, off - 0)

# Support No u w fi

#==========

tsolm=[1 1 1 1; % node 1

5 1 1 1]; % node 5

#==========

# ------------- Element properties, topology and hinges --------- elasts=[# Element properties # n2 - end of the element # n1 - beginning of the element # N, Q, M - hinges at the end of the element # N, Q, M - hinges at the beginning of the element # Mpl - plastic moment at the end of the element # Mpl - plastic moment at the beginning # of the element EIp EAp GAp 2 1 0 0 0 0 0 0 0.0 0.0 ; % element 1 EIr EAr GAr 3 2 0 0 0 0 0 0 0.0 0.0 ; % element 2 EIr EAr GAr 4 3 0 0 0 0 0 0 0.0 0.0 ; % element 3 EIp EAp GAp 5 4 0 0 0 0 0 0 0.0 0.0 ]; % element 4 # 1 - hinge 'true' (axial, shear, moment hinges) #

2. Assembling and solving the boundary problem equations (8.1), carried out by the function

LaheFrameSnDFIm(baasi0,Ntoerkts,esQkoormus,esFjoud,sSolmF,tsolm,tSiire, krdn,selem).

This function gives the unscaled initial parameter vectors of the elements and support reactions according to the load cases.

3. Output data.

Load case 1. The load factor

(Flambda0), forces

(Flambda0), forces  (F3s03) and

(F3s03) and

(F2s03) are given in excerpt 8.1 from the computing diary.

(F2s03) are given in excerpt 8.1 from the computing diary.

Flambda0=15/AbsmaxminM Flambda0 = 14.685 -------------- F2s = 0.50000 F2s03=Flambda0*F2s F2s03 = 7.3427 --- F3s = 1 F3s03=Flambda0*F3s F3s03 = 14.685 ============== plastF1F2=[Flambda0 F2s03 F3s03] plastF1F2 = 14.6853 7.3427 14.6853 save myfile30.mat plastF1F2

The bending moments of the first loading case are given in excerpt 8.2 from the computing diary, and the bending moments diagram is shown in Fig. 8.2(a).

Moments at nodes (Sign Convention 2) ============================================================== Node Moment DaF No Fi/baasi0 DaF No Work_b Element -------------------------------------------------------------- 1 0.26429 12 0.00000e+00 9 0.00000e+00 1 2 -0.12143 6 -3.85714e-05 3 4.68367e-06 1 2 0.12143 24 -3.85714e-05 21 -4.68367e-06 2 3 1.42857 18 5.00000e-06 15 7.14286e-06 2 3 -1.42857 36 5.00000e-06 33 -7.14286e-06 3 4 -1.02143 30 1.85714e-05 27 -1.89694e-05 3 4 1.02143 48 1.85714e-05 45 1.89694e-05 4 5 0.83571 42 0.00000e+00 39 0.00000e+00 4 -------------------------------------------------------------- Note. Work_b is done by boundary forces of an element

Load case 2.

The bending moments of the second loading case are given in excerpt 8.4 of the computing diary.

The bending moments diagram is shown in Fig. 8.2(b).

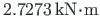

We find that the next node at which a full plastic moment

will appear

is node 5 (DaF = 42, see computing diary excerpt 8.3, Figs. 8.8 and 8.2(b)).

At this node,

will appear

is node 5 (DaF = 42, see computing diary excerpt 8.3, Figs. 8.8 and 8.2(b)).

At this node,

(deltaM0)

is to be added as shown in excerpt 8.3 and Fig. 8.3(a).

(deltaM0)

is to be added as shown in excerpt 8.3 and Fig. 8.3(a).

The maximum absolute values of reduced moments AbsmaxminM = 12.273 muutujaDaF1 = 42 deltaM0=15.0-AbsmaxminM deltaM0 = 2.7273 Flambda0 = 14.685 deltaM0 = 2.7273 muutujaDaF1 = 42 save myfile31.mat Flambda0 deltaM0 muutujaDaF1

Moments at nodes (Sign Convention 2) ============================================================== Node Moment DaF No Fi/baasi0 DaF No Work_b Element -------------------------------------------------------------- 1 3.88112 12 0.00000e+00 9 0.00000e+00 1 2 -1.78322 6 -5.66434e-04 3 1.01007e-03 1 2 1.78322 24 -5.66434e-04 21 -1.01007e-03 2 3 20.97902 18 7.34266e-05 15 1.54042e-03 2 3 -20.97902 36 7.34266e-05 33 -1.54042e-03 3 4 -15.00000 30 2.72727e-04 27 -4.09091e-03 3 4 15.00000 48 2.72727e-04 45 4.09091e-03 4 5 12.27273 42 0.00000e+00 39 0.00000e+00 4 --------------------------------------------------------------